1. ISO/TS 11139 Terms and definitions in sterilization standards

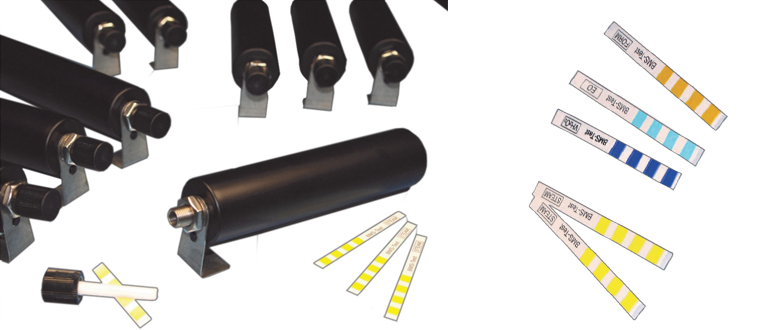

2. EN ISO 11138 Biological indicators to test sterilization processes

- Part I General requirements

- Part II for ethylene oxide sterilization (strips and self-contained)

- Part III for moist heat sterilization (strips and self-contained)

- Part IV for dry heat sterilization

- Part V for low-temperature-steam-formaldehyde sterilization

- Part VI for hydrogen peroxide vapour sterilization processes (Draft)

EN ISO 14161 Guidance for the selection, use and interpretation of results for the validation and routine monitoring of the sterilization of medical products with biological indicators

3. EN ISO 11140 Non-biological (chemical) indicators to test sterilization processes

- Part I Classification and general requirements (of classes 1-6)

- Part II not applicable (DIN EN ISO 18472)

- Part III Requirements Bowie-Dick test sheets

- Part IV Test procedure for the Bowie-Dick-Simulation Test for steam penetration according to the

European standard EN 285 (7 kg) - Part V Test procedure for the Bowie-Dick-Simulation Test for air removal (only ISO) according to the AAMI test pack (4 kg)

- Part VI Class 2 indicators and process challenge devices for use in performance testing for steam sterilizers

EN ISO 15882 Guidance for selection, use and interpretation of results for chemical indicators

(currently updated to conform with the new EN-ISO 11140 Standard)

4. Standards for validation of medical devices

EN ISO 17665 Requirements for the development, validation and routine control

(replaces EN 554) of steam sterilization processes

- Part I Requirements

- Part II Guidance

EN ISO 11135 Requirements for the development, validation and routine control(replaces EN 550) of ethylene oxide sterilization processes

- Part I Requirements

- Part II Guidance

EN ISO 11137 Radiation sterilization(replaces EN 552) Part I Requirements for validation and routine control

- Part II Selection of dose setting for products

- Part III Guidance

EN ISO 14937 General requirements for the characterization of sterilization products and the

development, validation and routine monitoring of sterilization processes

EN 15424 Validation of Low Temperature-Steam-Formaldehyde (LTSF) Processes

EN ISO 17664 Information to be provided by the manufacturer for the processing

of re-sterilizable medical devices

ISO 14971 Application of risk management to medical devices

5. EN 868 Packaging materials for sterilization

- Part I replaced by EN ISO 11607-1

- Part II Requirements and tests for sterilization wraps

- Part III Requirements and tests for paper to manufacture bags

- Part IV Requirements and tests for paper bags

- Part V Requirements and tests for heat sealable pouches and reel material made of paper

and/or plastic and/or laminates - Part VI Requirements and tests for paper to manufacture bags for ethylene oxide and

irradiation sterilization - Part VII Requirements and tests for adhesive coated paper to manufacture bags for ethylene

oxide and irradiation sterilization - Part VIII Requirements and tests for reusable containers

- Part IX Uncoated non-woven materials of polyolefines for use in the manufacturing of heat sealable

pouches, reels and lids – Requirements and test methods - Part X Adhesive coated non-woven materials of polyolefines for use in the manufacturing of heat

sealable pouches, reels and lids